Bulloneria del toce – Disaster recovery

- Home

- Case Studies

- BULLONERIA DEL TOCE – disaster recovery

Bulloneria del Toce case study highlights the importance of the Service in LCS. A growing sector, well organized and ready to intervene even in cases of strong and sudden unease.

The company and the fact:

Founded in 1979, the Bulloneria del Toce company is a leader in the production of bolts, screws and products for metal fastening in general. Quality of materials and service reliability are the strengths of an activity with a strong know-how in the production of round head screws with square, screws for the industrial, agricultural, silos, electrical, mechanical and automotive sectors. An experience of over 40 years in constant search for innovations and new markets.

The entire company production is concentrated in the Baveno (VB) plant, where in October 2020 rainfall of exceptional intensity occurred which caused various damages in the area. Specifically, on October 3, the peak of rainfall moves to the Verbano area, causing the flood of the Toce River which causes flooding in various areas. The industrial area of Baveno was one of those affected, where the Bulloneria del Toce company stands, which found itself with the plant, and in particular the automatic warehouse, submerged by a meter of mud, water and debris.

The damage count and the intervention

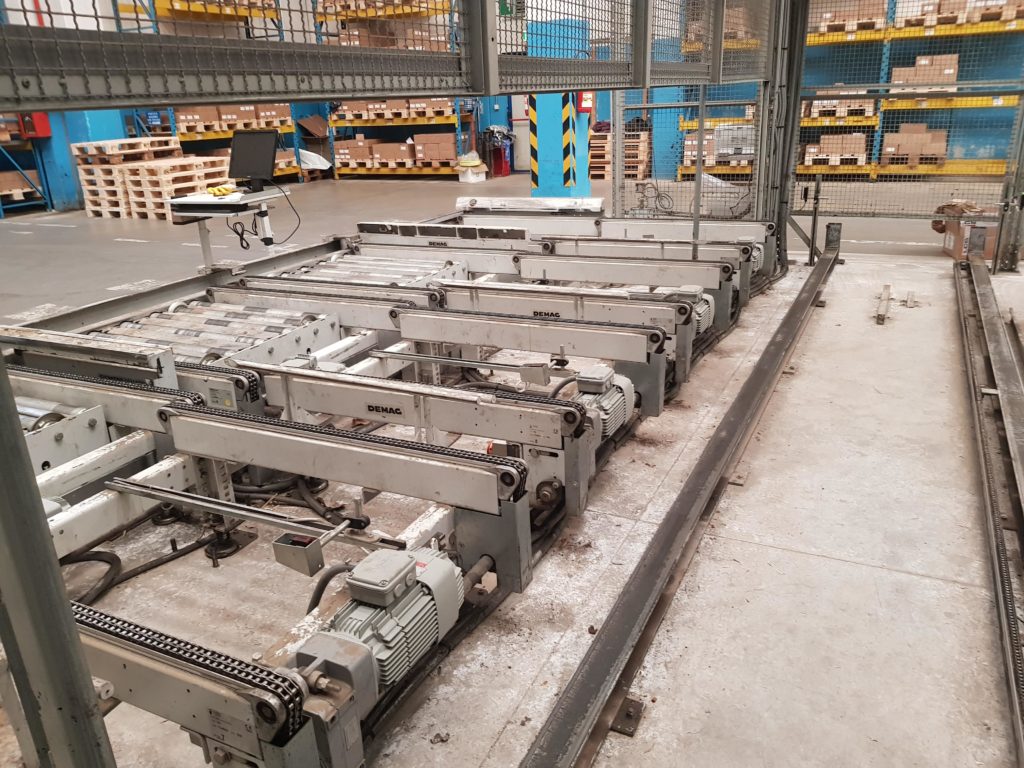

The mix of mud and water had compromised most of the sensitive points of the plant: the motors of the 50 pallet carriers that make up the handling system (located 40 cm. from the ground and therefore completely submerged), the motor of the two stacker cranes present in the company, the busway where the 400 volt power supply passes which powers the machines, all the electrical cables with their control units, without forgetting the cast iron wheels, gears and lubrication systems…

First of all, the damage count was made: before working on the machinery it was good to understand what could be saved and what not. The day after the flooding, the LCS technicians went to the company for an in-depth assessment, on that occasion the entire system was disassembled, from the motors, to the sensors, from the control unit to the photocell. Specifically, each electric motor was opened, the junction boxes were unblocked, the electrical cables checked, the oxidation and rusting of the metal parts and the deterioration of the magnetic parts were checked. All this for fifty elements weighing about 60 kg each which, together with the stacker crane motors (300 kg each) were sent to a specialized workshop for restoration and then reassembled and restarted.

Particular attention was then paid to the electrical components, the sheaths that wrap the metal cables were checked and the disconnectors in each control unit were cleaned so that the safety of the restarting of the system was guaranteed.

A long and demanding job was undertaken, also due to the working methods conditioned by the anticovid procedures but which made it possible to shorten plant downtime, so that the customer could quickly resume their business.

A miracle of efficiency from a win-to-win perspective

LCS was a successful bet. The first tests began on 23 October, first manually and then automatically and five days later, the Toce Bolts plant was fully back in operation. The speed of service and the skills of LCS in the electromechanical and automation fields have allowed the emergency to return in a short time and with the least economic loss for the company.

But the promptness of intervention is only one of the results achieved by the LCS service, the other, very important for the customer, concerns the economic impact of the restoration, much lower than a total replacement of the damaged elements.

A winning win-to-win perspective that has seen as protagonists not only the mutual collaboration between LCS and Bulloneria del Toce, which over the years have been able to build a profitable partnership, but also the collaboration between all the private partners that have allowed the rapid return to corporate operations, allowing Bulloneria del Toce to resume operations by contending for damages from an event that could have led to worse consequences.